By: admin

Ankara, Turkey, June 10, 2021

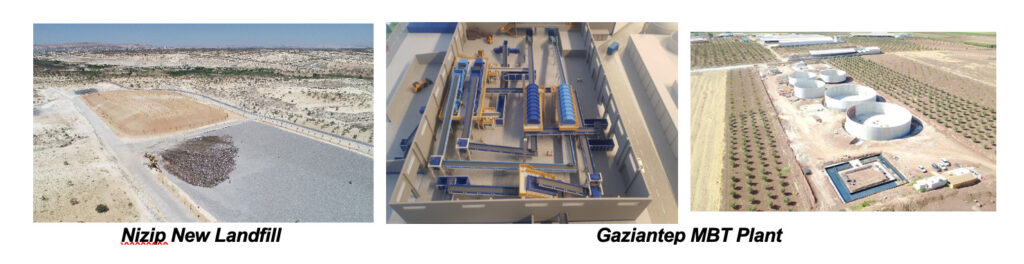

Aim Texas Overseas Management Group (AIMOMG) has attended a tender in joint venture with Erbil Project Consulting (Turkey), whereas Aim Texas is Lead Consultant in providing consulting Services for Consultancy Services for Design Review, Preparation of Bidding Documents and Construction Supervision Services for Gaziantep Mechanical Biological Treatment and Biogas Production Plant – Capacity Increase (2nd Stage), CHP unit and RDF production unit, Nizip Solid Waste Landfill (3rd Stage), Mechanical Recycling and RDF production unit and Rehabilitation of Dump sites and Şanlıurfa Viranşehir-Ceylanpınar Integrated Solid Waste Management Project (AFD2-C1)

ILBANK of Turkey has applied for a financing from Agence Française de Développement (“AFD”) and intends to use part of the funds thereof for payments under the following project Municipal Services Project II.

The Services of the consultant shall consist of design review, preparation of bidding documents, technical assistance during the bidding stage, and works supervision during construction stage and defects liability period (DLP) services for the following solid waste Sub-project investments.

- Gaziantep MBT and Biogas Production Facility-Capacity Increase (2nd Stage),

- Gaziantep Nizip Solid Waste Landfill (3rd Stage), mechanical recycling and RDF production unit and Rehabilitation of Dump Sites,

- Şanlıurfa – Viranşehir – Ceylanpınar Integrated Solid Waste Management Project.

The Consultant’s Services will be implemented over following two main phases:

- Phase-1 (Lump-Sum): Depending on the project’s stage, design review, preparation or review of related Employer’s Requirements, Conceptual Design (and/or reviewing available Conceptual design), Preparation of Design & Built Tender Dossiers whose Contract Conditions will be FIDIC, and Technical Assistance during the bidding and evaluation period.

- Phase-2 (Time Based): Design approval of the Works Contractor in Design and Built Contracts, Supervision of construction works and defects liability period (DLP)

The estimated duration of the Services is seven (7) months for Phase-1 (Preparation of Design & Built Tender dossier including Contract Conditions preparation period is 3 months + Bidding & Evaluation period is 4 months) and thirty-six (36) months for Phase-2 including twelve (12) months of Defects Liability Period (DLP). The total required time input for the Key Experts is estimated at this stage to be 463 person-months. This does not include the required time input from personnel other than the Key Experts.

Location of Services

Phase 1: For the design and procurement stage, substantial presence on site will not be required, provided regular communication is made possible with ILBANK’s representatives (in Ankara) and representatives of the municipalities in coordination with ILBANK’s representatives. However, site visits (in Gaziantep, Nizip and Şanlıurfa Cities) will be required from the beginning, and especially during preparation of design & built tender dossiers.

Phase 2: Substantial presence will be required on site. The location of Phase 2 services will be mainly within the region of Gaziantep, Nizip and Şanlıurfa Cities and around.

Gaziantep has population around 2,069,000 by 2019, which is located in the westernmost part of Turkey’s Southeastern Anatolia Region. Nizip is the largest surrounding district of Gaziantep with a population around 150,000, and located 45 km from the city of Gaziantep easterly.

Şanlıurfa is a city with a population of over 2 million residents in southeastern Turkey, and the capital of Şanlıurfa Province.

The Gaziantep Metropolitan Municipality (GMM) plans to implement the second stage of Mechanical Biological Treatment & Biogas Production Plant. The project area covers 7 of 9 districts of GMM serving a total of 1.876 million inhabitant plus 375 thousand Syrians refugees. The landfill in Gaziantep center now receives more than 500,000 tons of waste per year from 7 of 9 districts of GMM, waste from the remaining 2 districts being sent to Nizip landfill. The project aims to:

- Increase the capacity of its current mechanical-biological sorting equipment – from 100,000 t/anuum to 300,000 t/annum, (i.e. additional equipment of 200,000 t/annum).

- Build a RDF (Refuse Derived Fuel) production unit – with a capacity of around 50,000 t/annum.

- Increase the capacity of biomethanization unit (anaerobic digestion) & install CHP (combined heat and power) unit, capable of treating 110,000 t/annum of organic waste and produce renewable energy.

This project will make it possible to produce 33.5 thousand t/annum of the recycled waste, 52.6 thousand t/annum of RDF, and 20,251 MWh per year of renewable energy.